TurboMAX – Turboblowers featured with air-foil bearings.

Air blowers are applicable for many industrial branches, they are widely used in natural environment protection for tanks’ aerification at water treatment plants. They are also used in cement industry, steelworks and petrochemical industry for transportation of powdered materials. In agricultural they are used for transportation and for drying seeds and other food products and also for providing oxygen to fish farms. Blowers can supply air for painting lines. They improve incineration at incinerating plants and hasten gas removal.

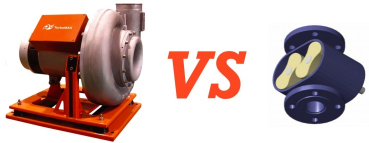

Among blowers a few basic constructions can be distinguished, at present time the most widespreaded are Roots blowers, gradually replaced by more efficient and economical constructions.

The state of the art devices are built on basis of air bearings and magnetic bearings, high speed motors and highly efficient impellers. Among our offering one can find turbo blowers featured with air-foil bearings, we belive, that it is the best product currently available on the market. It stands out with construction modernity and some significant exploitation advantages over devices featured with magnetic bearings, so to say: lack of additional induction systems, lower exploitation costs and much lower repair costs.

TurboMAX – Turbo blowers featured with air-foil bearings

The turbo blower is characterized by very high efficiency, achieved thanks to merged technology of air-foil bearings and high-speed motor featured with permanent magnets. Comparing to traditional Roots blower, above mentioned solution provides decrease of electrical energy consumption over 30%.

TurboMAX turbo blower featured with air-foil bearings compared with traditional blowers:

- No need for oil replacement;

- No need for any additional grease and oil system and relevant oil filters, temperature and oil pressure gauges, switches of high oil temperature, seals and filters of oil system;

- No grease-lubricated ball bearings;

- No motor brushes – permanent magnet built in rotor – no wearing elements;

- Energy saving, smooth performance regulation by means of inverter;

- No power losses at gears, motor shaft connected with impeller without a coupler;

- Due to the state of the art design, characterized by very high efficiency, considerably lower energy consumption as compared with traditional constructions;

- Compact design, all core elements: blower, inverter, controller, are located in a common enclosure, no need for additional external control cabinets;

- No vibration, very low noise level, approx. 10-15 dB(A) below conventional blowers’ noise level;

- No additional cooling devices for mixers of power up to 150 kW;

- Very low maintenance costs, only intake air filter has to be cleaned and replaced periodically;

Air-foil bearings features

- No oil, no oil-supplying systems;

- Low noise level and no vibration thanks to non-contact operating;

- Low impact of environmental factors, such as temperature;

- Maintenance and repairs are not necessary due to very high reliability, as a result of non-contact operating;

- Very long life-span – tests showed that after 20000 starts and stops, there was no wearing tracks on the bearings’ surface;

- High reliability proved in numerous installations;

- Tried and true technology, proved in military airplanes of US Army and airliners;

- Purposed for operating with high rotating speed;

Features of high-speed motor with permanent magnets

- Synchronous motor with permanent magnets;

- High power, small dimensions;

- Precise speed adjustment achieved due to accurate control by means of inverter;

- Power is transmitted in 100% because motor and impeller are connected directly, without a coupler;

- Effective cooling system improves motor’s lifespan by keeping the temperature low during operating;

- In motor’s rotor there are permanent magnets built-in; only motor’s stator consumes electric power in order to generate electromagnetic field;

- Brushless motor – no wearing elements;

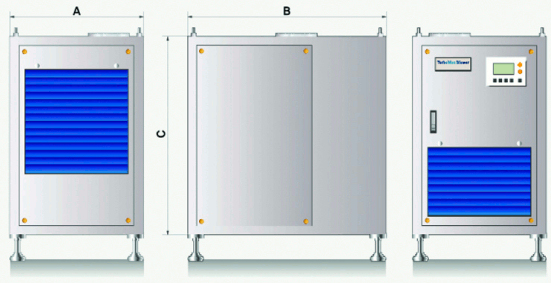

MODELS

The following blower’s models are available.

| Model | Power [hp] | Power [kW] | Dimensions [mm] | Weight* [kg] | ||

| A | B | C | ||||

| MAX 30 | 30 | 22 | 750 | 1000 | 800 | 390 |

| MAX 50 | 50 | 37 | 750 | 1000 | 800 | 390 |

| MAX 75 | 70 | 56 | 800 | 1200 | 1200 | 450 |

| MAX 100 | 100 | 75 | 850 | 1300 | 1450 | 500 |

| MAX 150 | 150 | 112 | 850 | 1700 | 1450 | 600 |

| MAX 200 | 200 | 150 | 950 | 1550 | 1450 | 700 |

| MAX 300 | 300 | 224 | 1100 | 1750 | 1850 | 850 |

* Weight without accessories, for particulars models its weight varies from 120 to 350 kg.

Efficiency for each model.

| Rated output pressure [kPa] | Rated flow [m3/min] | ||||||

| MAX 30 | MAX 50 | MAX 75 | MAX 100 | MAX 150 | MAX 200 | MAX 300 | |

| 40 | 21 | 41 | 63 | 79 | 131 | 165 | 245 |

| 60 | 16 | 31 | 50 | 63 | 95 | 136 | 190 |

| 80 | 13 | 25 | 38 | 51 | 76 | 102 | 152 |

| 100 | 10,5 | 20 | 31 | 42 | 62 | 83 | 125 |

| 120 | 9,5 | 18 | 28 | 37 | 56 | 75 | 112 |

| 150 | 8 | 15 | 23 | 31 | 47 | 63 | 94 |

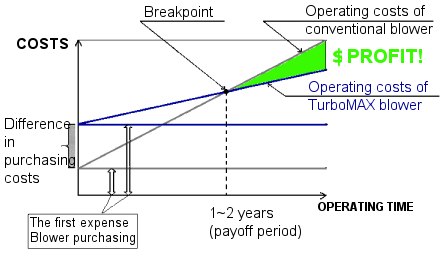

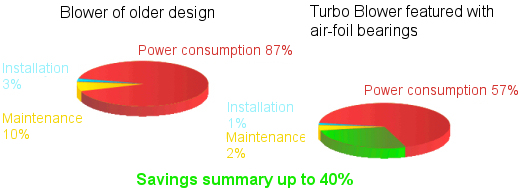

COST-EFFECTIVENESS

Air-foil bearings turbo blower – why does this purchase pay?

Significantly lower electrical energy costs:

- Significantly lower electric energy consumption derived from construction’s modernity;

- No energy losses at gears;

- No energy losses at transport belts;

- No energy losses relevant with bearings friction;

- No energy consumption by elements of oil system, for example: pump;

- High impeller efficency 80~85%;

- Low energy consumption contributes to natural environment protection, this is very important trait in case of every prospective investments;

Low installation costs:

- Small dimensions, compact construction for easy installation and transportation;

- No need for special base plate due to low weight and lack of vibrations;

Low maintenance costs:

- Maximum simplisticed handling and maintenance generate significantly lower costs;

- Only inlet air filter goes under regular maintenance replacements;

- No costs connected with oil’s replacement and utilization, rotor’s shafts replacement, etc.

Example. As already wrote, one of the most important traits of air-foil bearings TurboMax blower is significantly lower electrical energy consumption. What benefits can be expected?

Every consumed kWh is an expense of:

0,50 zł/kWh + VAT (data as for year 2010, cost may vary depending upon individually negotiated rates)

Lets assumpt, that the blower is operating for 320 days per year:

320 days · 24 h/day = 7680 h/year

So, energy consumption lower just by 1 kWh generates yearly savings equal to:

1 kWh · 0,50 zł/kWh · 7680 h = 3.840,00 zł net

Air-foil bearings turbo blower of the same performance as comparable Roots blower is characterised by energy consumption lower by approx. 35%.

| Rootsa blower | TurboMAX blower with air-foil bearings | |

| Power consumption | 100 kW | 65 kW |

Savings equal to 35% just because of lower electrical energy consumption!

The result converted to money means, that yearly energy savings are equal to:

So lower electrical energy consumption generates significant savings. In this calculation savings due to lower installation and exploitation costs shouldn’t be neglected.

As above example indicates air-foil bearings blower will contribute to great savings in longer time period.