AS Mixers

Submersible mixers with direct drive

OVERWIEV

Submersible mixers of group AS are designer as machines with propeller directly mounted at a shaft of multi-pole electric motor. In the result a robust, compact and relatively light item comes into existence. Purposed for duty in submersion it has a wide range of applications. Besides waste water treatment plants mixers of this type are applied in agriculture, at drinking water stations, in chemistry and many other industrial areas where exploitation conditions frequently are quite unfriendly.

Due to a small propeller diameter and high propeller velocity thrust generated by agitators of group AS has a quite big strength but at the relatively short distance and within the relatively narrow cross-section of flow volume. The shape of the agitated flow and its range can be additionally modified by means of dedicated jet-ring.

Mixers with direct drive are usually applied for small technological basins of for tanks with difficult, complicated geometry. By means of these machines a detailed, perfect blending of so called "dead zones" areas, for instance in tank corners, can be done. Correctly located mixers of AS type make possible a precise and efficient mixing of especially small chambers, sludge wells or pump stations and therefore they are perfect everywhere if only the intensive and strong action is required.

The undisputable advantage of direct drive mixers is the fact that due to a small diameter of propellers and related lightness of guide systems they are suitable for relatively shallow tanks. Therefore, with different versions of body and in several options of propellers, AS agitators can be applied for mixing of pig or cow manure or for other aggressive mediums as well.

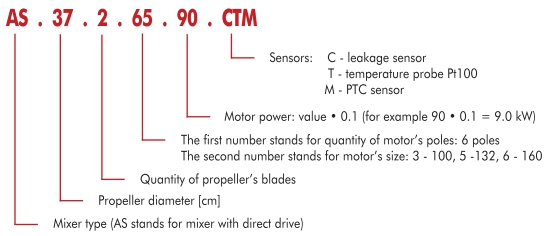

DESIGNATION

SIZES

Submersible mixers with direct driver of AS type are featured with stainless cast steel propellers of diameters from 220 mm up to 480 mm, two or three blades, power varies from 0,7 kW to 11 kW, RPM from 475 up to 1450.

| Mixer model | Propeller diameter [mm] | Number of propeller blades | Number of motor poles | Motor size | Motor power [kW] |

| AS.22 | 220 | 2, 3 | 4 | 3 | 2,2 |

| 3,0 | |||||

| 4,0 | |||||

| AS.30 | 300 | 2, 3 | 6 | 3 | 1,5 |

| 1,8 | |||||

| 2,2 | |||||

| 4 | 5 | 5,5 | |||

| 7,5 | |||||

| 9,2 | |||||

| 11,0 | |||||

| 6 | 5 | 3,0 | |||

| 4,0 | |||||

| 5,5 | |||||

| 7,5 | |||||

| 8 | 3 | 0,75 | |||

| 1,1 | |||||

| 8 | 5 | 2,2 | |||

| 3,0 | |||||

| 4,0 | |||||

| AS.37 | 370 | 2, 3 | 6 | 5 | 3,0 |

| 4,0 | |||||

| 5,5 | |||||

| 7,5 | |||||

| 8 | 5 | 2,2 | |||

| 3,0 | |||||

| 4,0 |

FEATURES OF STANDARD VERSION OF AS MIXERS

- Propellers geometry guarantees maximum efficiency while maintaining energy consumption on low level; self-cleaning design, special shape of blades prevents solid particles from settling down;

- Propellers entirely made as one-piece stainless steel cast; casting technology allows us to produce propellers featured with diversified thickness of blades, which significantly improves generated thrust; propellers are available in two versions: with two or three blades;

- Two independent leakage sensors located in motor chamber and cable terminal case; due to its arrangement sensors guarantees detection of even smallest quantities of liquid; related electronic module allows to switch off mixer immediately;

- Three bimetal thermo-contacts, located at each of motor’s phases; contacts stop the motor if temperature limit equal to 145 C degrees is exceeded; winding of the motor covered with double insulation layer of class F;

- Electronic module cooperating with leakage and temperature sensors; purposed for installation within control cabinet which should be located on the platform. Each electronic module is composed of controller and power feeder. Electronic modules collect signals from sensors and send appropriate information to central control system;

- Mixer’s body and covers made o Grey cast iron, covered with multilayer epoxy coating; strong resistance against corrosion;

- Double mechanical SiC/SiC seals, located in buffer chamber filled with oil; effectively protects mixer against leakage from the front side;

- Labyrinth and lip seals protect the double mechanical seal against bad impact caused by solid particles; significantly improves mixer’s life-span and malfunction-free period;

- All static connections sealed by means of O-rings packs, additionally assured with Loctite sealant;

- Power cable of 10 m length, made of special materials, capable for long operations in submersion, even in aggressive environment;

- Cable gland providing total leak tightness and protecting cable against being accidentally pulled out;

- Solid design guarantees high mechanical durability and long-term, malfunction free exploitation under any conditions.

AVAILABLE OPTIONS OF AS MIXER

- Mixer’s body and covers made as one-piece casts made of stainless or acid-proof cast steel, perfect for operation in particularly aggressive and harsh environment as well as for every application where the highest quality is required;

- Propellers made as one-piece, acid-proof steel casts;

- Outer layer made of paint with ceramic additions, characterized by strong mechanical resistance;

- Additional temperature probe Pt100 located at one of stator’s phases, purposed for Reading current value of motor’s wirings temperature;

- Additional PTC sensors, providing the same functionality as thermo-contacts;

- Motors with insulation class H;

- Control cabinet for installation around mixer, composed of control and power elements; it can be used both for manual mixer’s control and for acting as a part of central control system;

- The following powering options are available: 380V, 60Hz; 400V, 50Hz; 460V, 60Hz.

CHECK

Example characteristic card – AS.37.85.22 mixer - download ![]()